Revelation of Urovo Testing Laboratories

Following the mobilization ceremony of Urovo Tech’s “Quality Campaign Month”, Urovo Tech’s quality control system is revealed to the public in stages. For this publication, Urovo Tech wishes to introduce to readers its rigorous testing laboratories.

Urovo Laboratories, which are located in our production base, currently house over 50 sets of instruments and tools. These advanced instruments and equipment include thermal shock test chambers, 2.5D image measuring instruments, and metallographic microscopes, to name a few. Scientific and accurate experiments, which are focused on high temperature, low temperature, temperature shock, salt spray, vibration, transportation, and more, can be conducted under GB2423, IEC60068, ISTA, and other standards. Urovo Laboratories play a crucial role in the entire process of the overall research and development, and manufacturing systems of Urovo Tech.

Urovo Laboratories are composed of four high-standard laboratories. Equipped with corresponding software and hardware development equipment and testing tools, these laboratories focus on the research and development of novel and cutting-edge products, and core technologies.

I. Hardware Development Laboratory for Smart Mobile Devices

This laboratory focuses its research on the fuselage materials, product appearance, and functional modules of our existing products, and advanced materials are used to strengthen the shockproof, anti-fall, and anti-aging features of existing products. In addition, research on multiple product appearances and functional module solutions is based on the personalization development trend in the market demand, ensuring that our moderately forward-looking product design can respond to market demands at any time.

Representative equipment:

Voltage endurance testing instrument: to test the endurance of a power adapter under extraordinarily high voltage.

According to the national standard GB/T 4943, Urovo Tech conducts a one-minute voltage endurance test of the primary circuit and the secondary circuit of the power adapter using 3,000-volt alternating current.

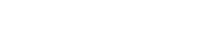

Bending tester: to test the life of a data cable or power cord that is bent repeatedly on a daily basis in a simulation.

According to the industrial standard, Urovo Tech hangs a 200-g data cable, and then bends it back and forth 3,000 times at the angle of 60°.

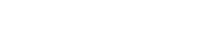

Paper abrasion tester:to test the abrasion resistance of screen printing, coating, plating, and painting of accessories and enclosures.

According to the industrial standards, Urovo Tech conducts an abrasion test ranging from 50 to 300 runs on various types of enclosures, including 50 runs on rubber paint and 200 runs on PU paint.

II. Product Testing Laboratory

This laboratory is committed to testing the performance of raw material modules, the performance of functional modules in development processes, the performance of semi-finished products, and the performance of prototypes. The entire control over product development processes will help detect problems in time and provide a basis for design improvement.

Representative equipment:

Temperature and humidity test chamber: to test the reliability of charging, operation, storage, and other measures of product performance in a climate with various temperatures and levels of humidity.

According to the national standard GB/T 2423, Urovo Tech will operate a product at a temperature of -10°C~50°C and a humidity level of 5%~95% after it is charged at a temperature of 0°C~45°C and a humidity level of 5%~95%, which will be stored in an environment with a temperature of -20°C~70°C and a humidity level of 5%~95%. Test requirements will be recalibrated to meet special circumstances as required by our clients. For instance, as for clients from Northern China, the temperature is lower in winter, as the extreme low temperature falls below -30°C. In this regard, the storage temperature will be adjusted to -40°C or even lower.

Drop tester: to test the ability of the free fallen product to withstand unexpected shocks in a simulation.

Urovo Tech’s drop test is mainly based on the actual use of the product in a simulation. For instance, the free fall requirement for handheld devices is 1.2 meters, while the free fall requirement for desktop devices is 0.8 meters.

Keypad life tester:to test the performance of the keys during the product lifecycle by tapping keys in a simulation.

After calculating the daily use life of a device, Urovo Tech performs 100,000 simulated taps on ordinary keys, and 500,000 to 1,000,000 simulated taps on critical keys, such as scan keys.

III. Structural Design Laboratory

This laboratory is dedicated for product structure designs as a reasonable structure not only enhances product function and stability, but also determines product costs to a certain extent.

Representative equipment:

Sand and dust test chamber: to test the enclosure sealing performance of a product, mainly used for the IP5X and IP6X tests specified in the enclosure protection standard.

Rain spray test chamber: to test the water-resistant performance of electronic products and their components exposed in all environments during their transportation and use, such as water spray and liquid spray.

Thermal shock test chamber: to determine the reliability of products or materials in a climate where there is a drastic change in the temperature.

According to the national standard GB/T 2423, Urovo Tech conducts temperature change tests for -20°C to 70°C (in case of electronic materials) and -40°C to 85°C (in case of metal and plastic materials), respectively.

IV. Software Development Laboratory

By consistently adhering to the philosophy of being a comprehensive provider for general mobile application service solutions, the Company provides hardware for smart mobile terminals and develops corresponding software that meets customer requirements, and our customers will be provided with a complete set of product and service solutions to maximize the added value of the product.

Urovo Tech always believes that its business strength is built on its brand and that the brand thrives on quality. Therefore, Urovo Tech will build cutting-edge laboratories to enhance business innovation and safeguard product development. By persisting in first-rate products in the product orientation of “high efficiency, high quality, and high benefit”, Urovo Tech is committed to becoming the most valuable cross-industry mobile application specialist in the global market.